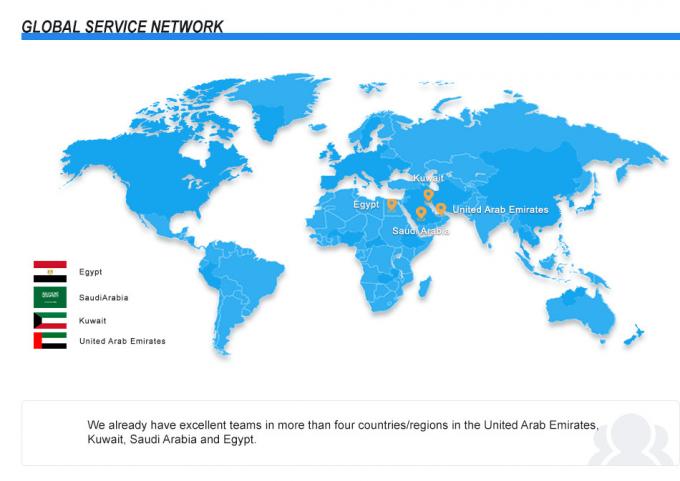

|

Product Details:

|

| Product Name: | CMS Series Casing Slip | Machine Type: | Wellhead Tools |

|---|---|---|---|

| Processing Type: | Casting | Material: | Iron |

| Usage: | Casing | Application: | Oil Field |

| Color: | Red/Yellow | Size: | 4-1/2"-30" |

| Capacity: | 125 Tons, 250Tons | Standard: | API 7K |

| Packing: | Standard Exported Package | ||

| High Light: | Wellhead Tools Casing Slips,CMS - XL Casing Slips,API 7K Casing Slips |

||

Drill Casing Slips Type CMS-XL Tubular Handling Tools API 7K For Drill Casing

Casing Slips description of Tubular Handing Tools

Slip consists of slip pieces, slip teeth and handles. The shape is a cone, which can be wedged into the inner hole of the turntable; The drill pipe slip is a three-piece structure connected by a hinge pin, and the drill collar slip and the casing slip are a four-piece structure connected by a hinge pin.

The CMS casing slips can accommodate casing from 4-1/2 to 30in(114.3 to 762mm).They are designed and manufactured in API 7K Slips for well drilling.It is manufactured in a structure of multi-segment pieces with firm structure, light weight , and large holding range, which is easy to fit the changing of the external diameter of the casing pipes due to wear and tear.

Casing Slips description of Tubular Handing Tools

There are many steel teeth on the inner wall of the slip. When working, the rotary device of the drill rig drives the slip to rotate, and the drill pipe rotates with the support of the slip.

The CMS casing slips are designed and manufactured in API 7K .It is manufactured in a structure of multi-segment pieces with firm structure, light weight , and large holding range from 4-1/2 to 30 in, with weight from 151.2 -550.2 lb, which is easy to fit the changing of the external diameter of the casing pipes due to wear and tear.

Instructions and maintenance of casing slips:

1. Select the corresponding slip according to the diameter of the drill pipe and the maximum load, and it is forbidden to exceed the applicable range.

2. Before use, pay attention to check that the hinge pin should rotate flexibly without sticking.

3. It is strictly forbidden to hit the back cone of the slip with a sledgehammer, or drop the slip from a height, so as not to damage the back cone.

4. Keep the slip surface clean to prevent rust.

| Casing OD | In | 4 1/2 | 5 | 5 1/2 | 6 5/8 | 7 | 7 5/8 | 8 5/8 | 9 5/8 | 10 3/4 |

| mm | 114.3 | 127 | 139.7 | 168.275 | 177.8 | 193.675 | 219.075 | 244.475 | 273.05 | |

| 2628-108 | 2619-108 | 2630-108 | 2628-144 | 2619-144 | 2630-144 | 2630-156 | 2630-168 | 2630-180 | ||

| Circular Buttons P/N | ||||||||||

| 9 | 9 | 9 | 12 | 12 | 12 | 13 | 14 | 15 | ||

| Total number of segments | ||||||||||

| Kg | 81 | 81 | 80 | 89 | 84 | 75 | 82 | 87 | 95 | |

| Weight | Ib | 176 | 176 | 174 | 196 | 184 | 166 | 181 | 192 | 209 |

| Use in insert Bowl number | API or No.3 | No.2 | ||||||||

| OD | In | 11 3/4 | 13 3/8 | 16 | 18 5/8 | 20 | 24 | 26 | 30 |

| mm | 298.45 | 339.725 | 406.4 | 473.075 | 508 | 609.6 | 660.4 | 762 | |

| 2627-204 | 2630-216 | 2631-252 | 2626-300 | 2631-312 | 2631-360 | 2631-396 | 2631-444 | ||

| Circular Buttons P/N | |||||||||

| 17 | 18 | 21 | 25 | 26 | 30 | 33 | 37 | ||

| Total number of segments | |||||||||

| Kg | 118 | 112 | 140 | 167 | 174 | 201 | 220 | 248 | |

| Weight | Ib | 260 | 247 | 308 | 367 | 383 | 443 | 486 | 546 |

Contact Person: Teresa Lyu

Tel: 18700951472

Fax: 86-021-61925822