|

Product Details:

|

| Product Name: | Integral Fittings | Size: | 1"-5" |

|---|---|---|---|

| Connection: | Threaded, Union | Working Medium: | Oil,natural Gas And Gas Containing H2S,CO2 |

| Surrounding Temperature: | -29℃~+121℃ | Working Pressure: | 2000 Psi ~ 20000 Psi |

| Material: | Carbon Steel, 4130, Stainless Steel | Service: | Standard |

| High Light: | API 6A Oilfield Wellhead Equipment,Fluid Control integral fittings,Oilfield Wellhead Equipment High Pressure |

||

API 6A High Pressure Fluid Control Integral Fittings Oilfield Wellhead Equipment

Oilfield Wellhead Equipment Integral Fittings Description:

Integral fittings are forged from high strength alloy steel, which are the most important flow distributing component in manifold connections. Through multiple crack detection, it reduces the defects in process flows. To minimize the size and weight of each integral fittings, engineers performed a finite element stress analysis on each ftting body design. Inner bores are chamfered to minimize the stresses in the tubular intersecting joints.

The integral fitting rough is forged of high-quality alloy steel. After heat treatment, it features compact structure, uniform wall thickness, long service life, beautiful appearance, strong interchangeability of joints and convenient connection. It is thickened on in elbow and joints where liquid changes direction and inner wall erosion is more serious, extending its safety service life.

Topland provides various of high pressure integral fittings, including tees,laterals, wyes, crosses, elbows, long radius elbows, adapters and so on.

Integral Fittings feature of Oilfield Wellhead Equipment

1. Integrate fitting includes 90° elbow, T-type tee, Y-joint, Cross, etc.

2. Nominal Diameter: 1" - 5"

3. Working Pressure: 7MPa-140Mpa

4. Material Grade: AA-EE

5. Temperature Rating: -29 ° C - + 121 ° C (PU); -46°C-+121°C (PL)

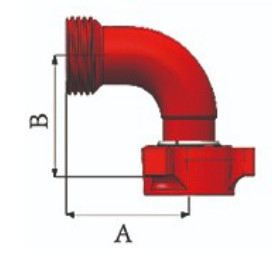

Elbows

| Normal Size | End Connections | Rated Working Pressure Mpa/Psi |

Dimensions(mm) | Service | ||

| A | B | |||||

| 2" | FIG1502 | FXM | 105/15000 | 154 | 154 | Standard |

| 2" | FIG1502 | FXF | 105/15000 | 154 | 154 | Standard |

| 2" | FIG1502 | MXM | 105/15000 | 154 | 154 | Standard |

| 3" | FIG1502 | FXM | 105/15000 | 214 | 214 | Standard |

| 3" | FIG1502 | FXF | 105/15000 | 214 | 214 | Standard |

| 3" | FIG1502 | MXM | 105/15000 | 214 | 214 | Standard |

| 3" | FIG2002 | FXM | 140/20000 | 257 | 257 | Standard |

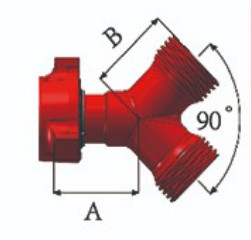

Laterals

| Normal Size | End Connections | Rated Working Pressure Mpa/Psi |

Dimensions(mm) | Service | ||

| A | B | |||||

| 2" | FIG1502 | MXFXF | 105/15000 | 400 | 250 | Standard |

| 2" | FIG1502 | MXFXM | 105/15000 | 400 | 250 | Standard |

| 2" | FIG1502 | FXFXF | 105/15000 | 400 | 250 | Standard |

| 3" | FIG1502 | MXFXF | 105/15000 | 533 | 355 | Standard |

| 3" | FIG1502 | MXFXM | 105/15000 | 533 | 355 | Standard |

| 3" | FIG1502 | FXFXF | 105/15000 | 533 | 355 | Standard |

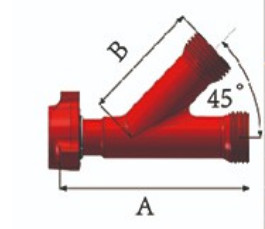

Wyes

| Normal Size | End Connections | Rated Working Pressure Mpa/Psi |

Dimensions(mm) | Service | ||

| A | B | |||||

| 2" | FIG1502 | MXFXF | 105/15000 | 133 | 127 | Standard |

| 2" | FIG2002 | MXFXF | 140/20000 | 148 | 127 | Standard |

| 3" | FIG1502 | MXFXF | 105/15000 | 200 | 203 | Standard |

| 3" | FIG2002 | MXFXF | 140/20000 | 270 | 270 | Standard |

Long Radius Elbows

| Normal Size | End Connections | Rated Working Pressure Mpa/Psi |

Dimensions(mm) | Service | ||

| A | B | |||||

| 2" | FIG1502 | FXM | 105/15000 | 171 | 162 | Standard |

| 2" | FIG1502 | MXM | 105/15000 | 171 | 162 | Standard |

| 3" | FIG1502 | FXM | 105/15000 | 203 | 225 | Standard |

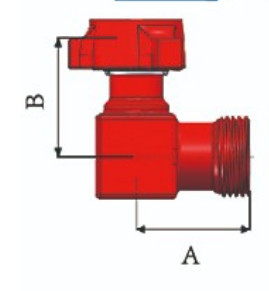

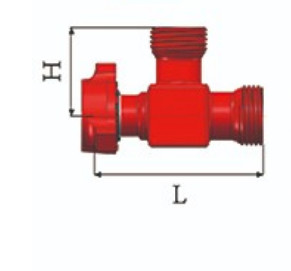

Tees

| Normal Size | End Connections | Rated Working Pressure Mpa/Psi |

Dimensions(mm) | Service | ||

| A | B | |||||

| 2" | FIG1502 | MXFXF | 105/15000 | 308 | 154 | Standard |

| 2" | FIG1502 | MXFXM | 105/15000 | 308 | 154 | Standard |

| 2" | FIG1502 | FXFXF | 105/15000 | 308 | 154 | Standard |

| 2" | FIG1502 | FXFXM | 105/15000 | 308 | 154 | Standard |

| 2" | FIG1502 | MXMXM | 105/15000 | 308 | 154 | Standard |

| 3" | FIG1502 | MXFXF | 105/15000 | 428 | 214 | Standard |

| 3" | FIG1502 | MXFXM | 105/15000 | 428 | 214 | Standard |

| 3" | FIG1502 | FXFXF | 105/15000 | 428 | 214 | Standard |

| 3" | FIG1502 | FXFXM | 105/15000 | 428 | 214 | Standard |

| 3" | FIG1502 | MXMXM | 105/15000 | 428 | 214 | Standard |

| 4" | FIG1502 | MXFXF | 105/15000 | 533 | 266.5 | Standard |

| 4" | FIG1502 | MXFXM | 105/15000 | 533 | 266.5 | Standard |

| 4" | FIG1502 | FXFXF | 105/15000 | 533 | 266.5 | Standard |

| 4" | FIG1502 | FXFXM | 105/15000 | 533 | 266.5 | Standard |

| 4" | FIG1502 | MXFXM | 105/15000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | MXFXF | 140/20000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | MXFXM | 140/20000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | FXFXF | 140/20000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | FXFXM | 140/20000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | MXMXM | 140/20000 | 533 | 266.5 | Standard |

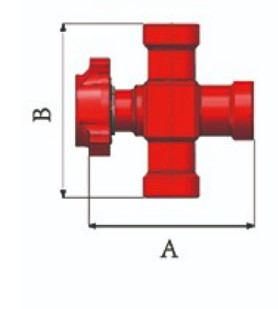

Crosses

| Normal Size | End Connections | Rated Working Pressure Mpa/Psi |

Dimensions(mm) | Service | ||

| A | B | |||||

| 2" | FIG1502 | MXFXFXF | 105/15000 | 308 | 308 | Standard |

| 2" | FIG1502 | MXFXMXF | 105/15000 | 308 | 308 | Standard |

| 2" | FIG1502 | MXMXMXF | 105/15000 | 308 | 308 | Standard |

| 3" | FIG1502 | MXFXFXF | 105/15000 | 428 | 428 | Standard |

| 3" | FIG1502 | MXFXMXF | 105/15000 | 428 | 428 | Standard |

| 3" | FIG1502 | MXMXMXF | 105/15000 | 428 | 428 | Standard |

| 4" | FIG1502 | MXFXFXF | 105/15000 | 533 | 533 | Standard |

| 4" | FIG1502 | MXFXMXF | 105/15000 | 533 | 533 | Standard |

| 4" | FIG1502 | MXMXMXF | 105/15000 | 533 | 533 | Standard |

FAQ

1. Who are we?

Topland is an integrated supplier established in 2008. We are a global group of oilfield supplies with excellent teams in more than 5 countries. such as UAE, Kuwait, Iran and Saudi Arabia. We cooperated with ADES, ECDE, EDC, SOCAR-AQS, PDL, SAKSON, ONGC etc.

2. How can we guarantee quality?

Always a double requirements and drawing checking before the production;

Always final Inspection before shipment;

3. What can you buy from us?

Drilling rig equipment and the related spares for the oil and natural gas industries. Like Rig Components, Drawworks Spare parts and Mud Pump Spare parts, Hydraulic Disc Brake,Solids Control Equipment, Drilling and Fishing Tools,Wellhead Control Equipment,Drilling Accessories, Cementing Equipment and Tools etc.

4. Why should you choose us?

4-1. Professional & Efficient, Customer Focus, Win-win Cooperation

4-2. Fast Quote, Competitive price & within shortest lead time

4-3. Complete Range of products, like spare parts which are interchangeable with most of the well-known OEM equipment.

4-2. Order tracking service

5. How is the packing?

All the packing will meet the strict export packing requirement, we surely know how important the beautiful and firm packaging to the goods.

6. What is your terms of payment?

A: Generally by T/T, 30% advance payment, the balance 70% payment should be paid before delivery. We support EXW, FOB, FCA, CFR, CIF, CIP, DAP, DDU and DDP INCO Terms.

Contact Person: Zoe Zou

Tel: + 8618392113679

Fax: 86-021-61925822