|

Product Details:

|

| Product Name: | High Pressure Fire-Resistance Bop Hose | Feature: | Fire-resistant,Adiabat,High Pressure Resistant |

|---|---|---|---|

| Proof Pressure: | 10000PSI | Connection: | Flange Or Union |

| Condition: | New | Temperature Range: | -40 To +120 Degrees |

| Weight: | 70kg/m | Application: | Petroleum Base Hydraulic Fluids |

| High Light: | Rubber Drilling Hose API 16D,Well Control Rubber Drilling Hose,API 16D Bop Hose |

||

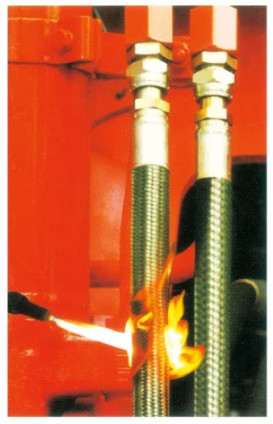

Well Control Rotary Rubber Drilling Hose API 16D High Pressure Fire-Resistance Bop Hose

BOP High Pressure Hose description of Rotary Drilling Hose

High-pressure fire-resistant insulated hose assembly for well control purpose is mainly used as the hydraulic pressure control pipe of drilling BOP and used for high-temperature furnace and flammable sites in the metallurgical industry. All the technical indexes of the hose assembly meet the API Spec 16D.

The inner core of the hose is made of saturated nitrile-butadience cyanide rubber, Teflon and some new-type nano-materials as well as auxiliary agents. It is acid-resistant, alkali-resistant, oil-resistant and high temperature-resistant.The middle layer of the hose is a steel wire reinforcement layer, which is made of viscous and solid gel.

The outer layer is an insulated fore-resistant layer with stainless steel outer case, which is made of the

compound of chloronorgutta rubber emulsified liquid, antimony trioxide and high silicon molecule with synthetic matter of surfactant carbon fiber.

Purposes: Applicable to connection at loctions when drill platform,semi-submersible diling vessel or diling vessel moves relatively and the installation dimensions of the drll rig subsequently change,and to delivery of oil,gas,mud and other high pressure media.

| Nominal ID (mm) |

Outside diameter(mm) | Working pressure(MPa) | Min.burst pressure(MPa) | Min.bending radius(mm) | Thread | Operating time(min)with fire-resisting at 750°C | |

| Normal | Limit | ||||||

| 6.3 | 24 | 35 | 105 | 130 | NPT LP | 5 | 25 |

| 26 | 70 | 175 | |||||

| 8 | 28 | 35 | 105 | 140 | |||

| 32 | 70 | 175 | |||||

| 10 | 30 | 35 | 105 | 160 | |||

| 34 | 70 | 175 | |||||

| 12.5 | 37 | 35 | 105 | 210 | |||

| 43 | 70 | 175 | |||||

| 16 | 41 | 35 | 105 | 260 | |||

| 47 | 70 | 175 | |||||

| 19 | 44 | 35 | 105 | 280 | |||

| 50 | 70 | 175 | |||||

| 22 | 47 | 35 | 105 | 320 | |||

| 53 | 70 | 175 | |||||

| 25 | 50 | 35 | 105 | 360 | |||

| 56 | 70 | 175 | |||||

| 31.5 | 56 | 35 | 105 | 460 | |||

| 62 | 70 | 175 | |||||

| 38 | 63 | 35 | 105 | 560 | |||

| 69 | 70 | 175 | |||||

FAQ

1. Who are we?

Topland is an integrated supplier established in 2008. We are a global group of oilfield supplies with excellent teams in more than 5 countries. such as UAE, Kuwait, Iran and Saudi Arabia. We cooperated with ADES, ECDE, EDC, SOCAR-AQS, PDL, SAKSON, ONGC etc.

2. How can we guarantee quality?

Always a double requirements and drawing checking before the production;

Always final Inspection before shipment;

3. What can you buy from us?

Drilling rig equipment and the related spares for the oil and natural gas industries. Like Rig Components, Drawworks Spare parts and Mud Pump Spare parts, Hydraulic Disc Brake,Solids Control Equipment, Drilling and Fishing Tools,Wellhead Control Equipment,Drilling Accessories, Cementing Equipment and Tools etc.

4. Why should you choose us?

4-1. Professional & Efficient, Customer Focus, Win-win Cooperation

4-2. Fast Quote, Competitive price & within shortest lead time

4-3. Complete Range of products, like spare parts which are interchangeable with most of the well-known OEM equipment.

4-2. Order tracking service

5. How is the packing?

All the packing will meet the strict export packing requirement, we surely know how important the beautiful and firm packaging to the goods.

6. What is your terms of payment?

A: Generally by T/T, 30% advance payment, the balance 70% payment should be paid before delivery. We support EXW, FOB, FCA, CFR, CIF, CIP, DAP, DDU and DDP INCO Terms.

Contact Person: Zoe Zou

Tel: + 8618392113679

Fax: 86-021-61925822