|

Product Details:

|

| Material: | NBR,EPDM,SILICONE,FKM,SBR,NR,etc. | Hardness Range: | 20-90 Shore A |

|---|---|---|---|

| Wall Thickness: | Standard Or Non-standard | Length: | 100pc |

| Feature: | Durable | MOQ: | 10 PIECES |

| Working Temperature: | -50℃~300℃ | Color: | As Required |

| High Light: | Silicone rubber o ring,silicone o ring Heat Resistance,EPDM rubber o ring |

||

Drilling Rig Spare Parts Heat Resistance ASTM Aflas NBR FKM EPDM Silicone Rubber O-Ring

O-Ring Description of Drilling Rig Spare Parts:

O-ring is a kind of rubber seal whose cross section is circular. NBR/Silicone/FKM/EPDM O rings are the most commonly used O FKMO ring is often used in the working environment that needs to resist of heat, chemical corrosion, oil, etc.

O-Ring Material:

| NBR (nitrile butadiene rubber) |

| Service Temperature For NBR the service temperature can be designed from -55 ℃ to 100℃ or up to 130℃ depe nding on differenacry lonirile content and formula. |

| Application NBR compounds have excellent resistance to abrasion, non- polar oils and solvent, water and permeation (higher acrylonitrile content will be better). NBR also can be used in conditions of dilute acids, alkalis and salt solution at low temperatures. |

| FKM (Fluoroc arbon) |

|

Service Temperature For general type veton the service temperature is better limited to approximately from -26 ℃ to 232 ℃ in static applications, though the service temperature can arrive to 275 ℃ at short time In dynamic applications, it is suitable between -15 ℃ and 200 ℃ |

| Application Because FKM has excellent resistance of high temperature, oil, solvent, flame, chemicals and weathering, it is usually applied in aulomotive, chemical processing, aerospace and many other industries. |

| Silicone Rubber o ring (Q, MQ, VMQ, PVMQ) |

| Service Temperature For Silic ones the service temperatures are from -60 ℃ to 225 ℃. Some special types can be used in extreme temperature up to 300 C and down to-100℃. |

| Application Silicone rubber performs well under environmental and temperature extremes.It is usually applied in automotive and aerospace industries where flexibility and longevity are important. It is also a suitable material for parts that need food grade for food handling equipment and appliances. |

FAQ

1. Who are we?

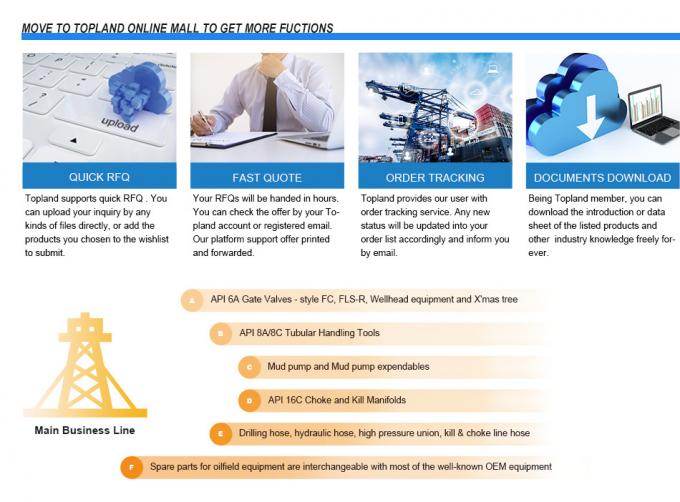

Topland is an integrated supplier established in 2008. We are a global group of oilfield supplies with excellent teams in more than 5 countries. such as UAE, Kuwait, Iran and Saudi Arabia. We cooperated with ADES, ECDE, EDC, SOCAR-AQS, PDL, SAKSON, ONGC etc.

2. How can we guarantee quality?

Always a double requirements and drawing checking before the production;

Always final Inspection before shipment;

3. What can you buy from us?

Drilling rig equipment and the related spares for the oil and natural gas industries. Like Rig Components, Drawworks Spare parts and Mud Pump Spare parts, Hydraulic Disc Brake,Solids Control Equipment, Drilling and Fishing Tools,Wellhead Control Equipment,Drilling Accessories, Cementing Equipment and Tools etc.

4. Why should you choose us?

4-1. Professional & Efficient, Customer Focus, Win-win Cooperation

4-2. Fast Quote, Competitive price & within shortest lead time

4-3. Complete Range of products, like spare parts which are interchangeable with most of the well-known OEM equipment.

4-2. Order tracking service

5: How is the packing?

All the packing will meet the strict export packing requirement, we surely know how important the beautiful and firm packaging to the goods.

6: What is your terms of payment?

A: Generally by T/T, 30% advance payment, the balance 70% payment should be paid before delivery. We support EXW, FOB, FCA, CFR, CIF, CIP, DAP, DDU and DDP INCO Terms.

Contact Person: Zoe Zou

Tel: + 8618392113679

Fax: 86-021-61925822