|

Product Details:

|

| Product Name: | Choke Valve/Cage Type Choke Valve/ Orifice Type Choke Valve | Key Words: | Mud Gate Valve |

|---|---|---|---|

| Media: | Water, Mud | Pressure: | 5000 PSI & 7500 PSI |

| Valve Size: | 1 13/16"~7 1/16" | Product Specification Level: | PSL1, PSL2, PSL3, PSL4 |

| End Connection Type: | Flange, Threaded, Butt-Welded, Hammer Union | Temp Class: | L, P, R, S, T, U, V |

| Specification Level: | PSL1-4 | Material: | AA,BB,CC,DD,EE,FF,HH |

| High Light: | Orifice Type Manifold Control Valve,Cameron Manual Adjustable Choke Valve,API 6A Manual Adjustable Choke Valve |

||

API 6A Cameron Manual Adjustable Choke Valve/Cage Type Choke Valve/ Orifice Type Choke valve

Description

Choke Valve consists of needle type adjustable choke valve, positive choke valve, barrel type choke valve, cage type choke valve and orifice type choke valve, mainly used in onshore and offshore oil drilling and exploitation. The design and quality control conform to international standards. Bodies are made of premium low alloy steel, processed with advanced technology in conformance with API 6A 20th edition and NACE MR-0175.

| Product name | Choke Valve |

| Working pressure | 2000-20000 PSI |

| Nominal bore | 1 13/16"~7 1/16" (46mm~180mm) |

| Working medium | oil,natural gas,mud and gas containing H2S,CO2 |

| Working temperature | -46℃—121℃ |

| Specification level | PSL 1- PSL4 |

| Performance requirement | PR 1-2 |

| Material class | AA,BB,CC,DD,EE,FF,HH |

| Manufacture standard | API Spec 6A |

Features

*Needle Type Choke Valve

Mainly used on wellhead Christmas trees

Valve plug and choke bean adopt high abrasion resistance hard alloy to endure long hours erosion and corrosion.

Open indicator and safe lock relief device.

Available with pressure relief valve.

Needle type choke valve and positive choke valve are interchangeable in body of the same size.

*Barrel Type Choke Valve

Used on choke and killing manifold to control casing pressure during drilling operation.

Easy flow adjustment, allowing stable flow.

Stem seal is made of special materials, delivering good chemical stability and corrosion resistance.

Valve plug and choke bean adopt high abrasion resistance hard alloy to endure long hours erosion and corrosion.

Barrel-shape gate, annular gap between gate and seat with entry and outlet connecting all the time, mainly used on choke manifold or other high pressure lines

*Orifice Type Choke Valve

Mainly applicable to drilling, fracturing, slurry circulation and land high pressure gas injection/production. During shutoff, the pressure differential between entry and outlet pushes two orifices tightly against each other for seal and cutoff.

In case of abrupt pressure change, the valve can automatically shut off by pre-set high and low pressure sensor.

Equipped with upper and lower orifices. The orifice open extent can control flow by turning the handwheel. Orifice adopts hard alloy to increase erosion and corrosion resistance. The valve can be used as a shutdown valve.

Allowing a smooth choke flow curve.

Inner bore of the outlet features extended wear bushing to extend service life.

Tubing head adapter on the outlet can be replaced depending on different pressure conditions.

Stem seal is made of special materials to deliver good chemical stability and corrosion resistance to medium.

*Cage Type Choke Valve

The cage type design enables fluid flowing along the cage centerline, avoiding erosion and corrosion to choke components and reducing noise.

Choke components adopt hard alloy tungsten carbide to deliver wide choking area, low noise and excellent resistance to erosion.

Metal-to-metal seal, easy maintenance

Annular space helps to reduce corrosion to body.

Low open/close torque, stable operation

Easy flow adjustment, allowing stable flow curve.

Stem seal is made of special materials to deliver good chemical stability and corrosion resistance to medium

Valve plug and choke bean adopt high abrasion resistance hard alloy to endure long hours erosion and corrosion.

FAQ

1. Who are we?

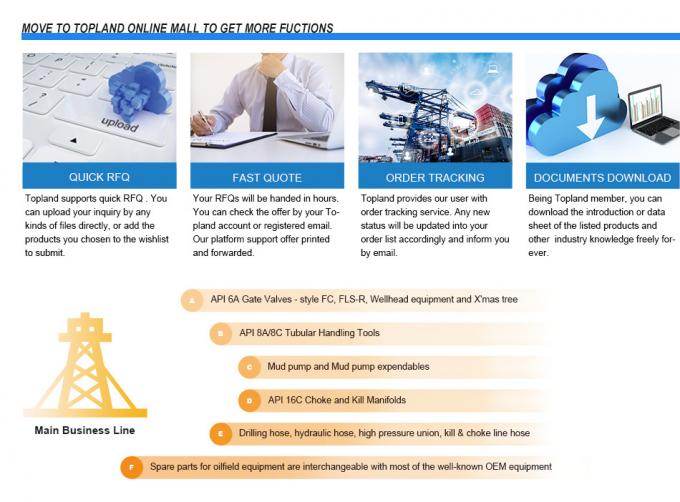

Topland is an integrated supplier established in 2008. We are a global group of oilfield supplies with excellent teams in more than 5 countries. such as UAE, Kuwait, Iran and Saudi Arabia. We cooperated with ADES, ECDE, EDC, SOCAR-AQS, PDL, SAKSON, ONGC etc.

2. How can we guarantee quality?

Always a double requirements and drawing checking before the production;

Always final Inspection before shipment;

3. What can you buy from us?

Drilling rig equipment and the related spares for the oil and natural gas industries. Like Rig Components, Drawworks Spare parts and Mud Pump Spare parts, Hydraulic Disc Brake,Solids Control Equipment, Drilling and Fishing Tools,Wellhead Control Equipment,Drilling Accessories, Cementing Equipment and Tools etc.

4. Why should you choose us?

4-1. Professional & Efficient, Customer Focus, Win-win Cooperation

4-2. Fast Quote, Competitive price & within shortest lead time

4-3. Complete Range of products, like spare parts which are interchangeable with most of the well-known OEM equipment.

4-2. Order tracking service

5. How is the packing?

All the packing will meet the strict export packing requirement, we surely know how important the beautiful and firm packaging to the goods.

6. What is your terms of payment?

A: Generally by T/T, 30% advance payment, the balance 70% payment should be paid before delivery. We support EXW, FOB, FCA, CFR, CIF, CIP, DAP, DDU and DDP INCO Terms.

Contact Person: Teresa Lyu

Tel: 18700951472

Fax: 86-021-61925822