|

Product Details:

|

| Type: | Metal Frame Screen | Core Components: | Screen |

|---|---|---|---|

| Standard: | API Standard | Mesh: | 20-325 |

| Condition: | New | Application: | Oilfield |

| HS Code: | 8431431000 | Material: | Stainless Steel |

| High Light: | Steel Screen Solids Control Equipment,Metal Frame Screen Solids Control Equipment |

||

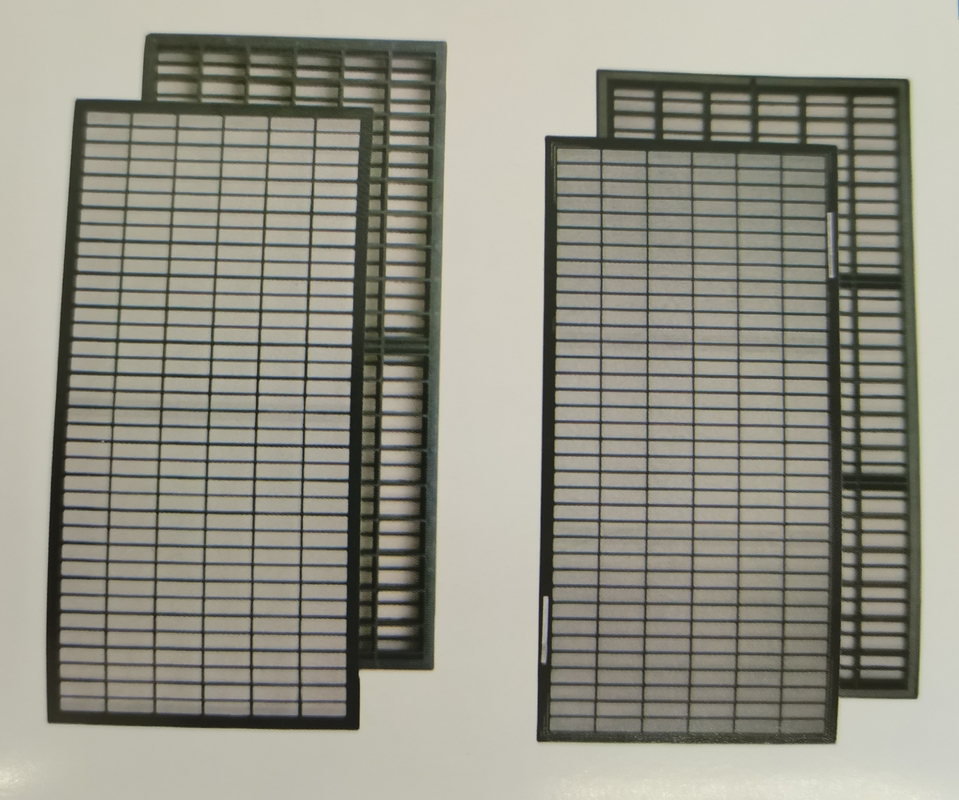

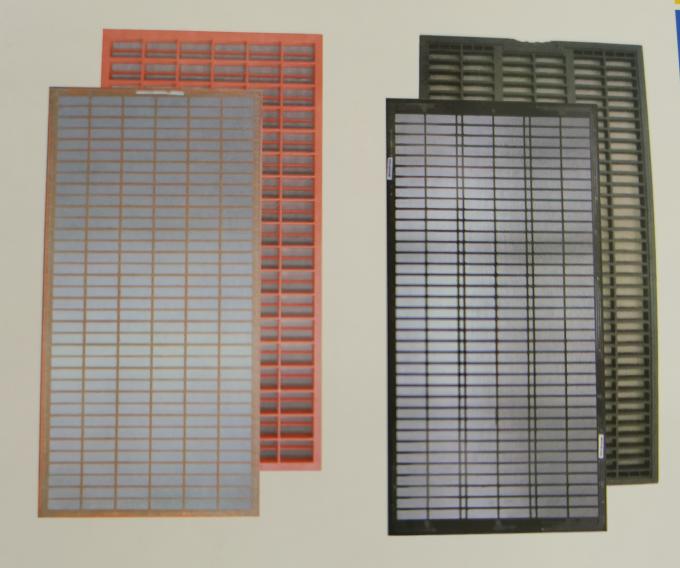

Replacement Steel Screen Solids Control Equipment Metal Frame Screen

Metal Frame Screen Description of Solids Control Equipment:

Steel Frame Screen is the most widely used screen,the features of screen of this type:

1.The stainless steel wire cloth combined directly bonded on the steel plank, then tightly bonded together by steel frames and metal plank.

2.Every layer of wire cloth has different meshes, accurately and reasonably making screening more micro mesh.

3.It forms a reliable whole, with high-strength steel frame, reinforced supports and moderate tension screening cloth, which greatly enhances the tolerate flow, strength and working life .Rapid wedge tensioning devices make screen installation more convenient, and save the time of machine halt for changing .

4. The surface is divided into more small parts. They can prevent excessive expansion of local damage. At the same time, we have the special rubber plug to repair the damage. It can save time and reduce the cost.

Metal Frame Screen Datasheet of Solids Control Equipment:

| Screen Model | Range of Mesh | Dimension(W*L) | Brand&Model of shaker |

| GMTK-1 | 20-325 | 585×1165mm | MONGOOSE |

| GMTK-2 | 20-325 | 635×1253mm | KING COBRA |

| GMTK-3 | 20-325 | 913×650mm | VSM300 |

| GMTK-4 | 20-325 | 720×1220mm | KTL48 SERIES |

| GMTK-5 | 20-325 | 712×1180mm | D380 |

| GMTK-6 | 20-325 | 737*1067mm | FSI 50&500&5000 |

| API RP 13C(ISO 13501) | |

| D100 Particle sizing (Microns) | API Screen Number |

| >780.0 to 925.0 | API 20 |

| >655.0 to 780.0 | API 25 |

| >550.0 to 655.0 | API 30 |

| >462.5 to 550.0 | API 35 |

| >390.0 to 462.5 | API 40 |

| >327.5 to 390.0 | API 45 |

| >275.0 to 327.5 | API 50 |

| >231.0 to 275.0 | API 60 |

| >196.0 to 231.0 | API 70 |

| >165.0 to 196.0 | API 80 |

| >137.5 to 165.0 | API 100 |

| >116.5 to 137.5 | API 120 |

| > 98.0 to 116.5 | API 140 |

| > 82.5 to 98.0 | API 170 |

| > 69.0 to 82.5 | API 200 |

| > 58.0 to 69.0 | API 230 |

| > 49.0 to 58.0 | API 270 |

| > 41.5 to 49.0 | API 325 |

FAQ

1. Who are we?

Topland is an integrated supplier established in 2008. We are a global group of oilfield supplies with excellent teams in more than 5 countries. such as UAE, Kuwait, Iran and Saudi Arabia. We cooperated with ADES, ECDE, EDC, SOCAR-AQS, PDL, SAKSON, ONGC etc.

2. How can we guarantee quality?

Always a double requirements and drawing checking before the production;

Always final Inspection before shipment;

3. What can you buy from us?

Drilling rig equipment and the related spares for the oil and natural gas industries. Like Rig Components, Drawworks Spare parts and Mud Pump Spare parts, Hydraulic Disc Brake,Solids Control Equipment, Drilling and Fishing Tools,Wellhead Control Equipment,Drilling Accessories, Cementing Equipment and Tools etc.

4. Why should you choose us?

4-1. Professional & Efficient, Customer Focus, Win-win Cooperation

4-2. Fast Quote, Competitive price & within shortest lead time

4-3. Complete Range of products, like spare parts which are interchangeable with most of the well-known OEM equipment.

4-2. Order tracking service

5. How is the packing?

All the packing will meet the strict export packing requirement, we surely know how important the beautiful and firm packaging to the goods.

6. What is your terms of payment?

A: Generally by T/T, 30% advance payment, the balance 70% payment should be paid before delivery. We support EXW, FOB, FCA, CFR, CIF, CIP, DAP, DDU and DDP INCO Terms.

Contact Person: Zoe Zou

Tel: + 8618392113679

Fax: 86-021-61925822